Engineers at the Massachusetts Institute of Technology have made a paper-thin loudspeaker that can turn any surface into an active source of sound.

This thin-film loudspeaker generates high-quality sound while using a fraction of the energy that a conventional loudspeaker of similar size would. The scientists showed that their loudspeaker, which is the size of a dime, can make high-quality sound no matter what surface the film is stuck to.

The researchers found a process that looks complicated but is actually very simple. It only takes three basic steps and can be scaled up to make ultrathin loudspeakers big enough to cover the inside of a car or wallpaper a room, for example.

These thin-film loudspeakers could be used to provide active noise cancellation in noisy locations such as an aeroplane cockpit, they produce sound with the same loudness but opposite phase, and when used in this manner, the two sounds cancel each other out.

Additionally, the adaptable gadget might be used to provide immersive entertainment in a variety of situations, such as three-dimensional audio in a theatre or a theme park ride. Furthermore, the device is good for smart phones with short battery lives because it is small and doesn’t use a lot of power.

The research was published in IEEE Transactions on Industrial Electronics.

A completely different approach was required.

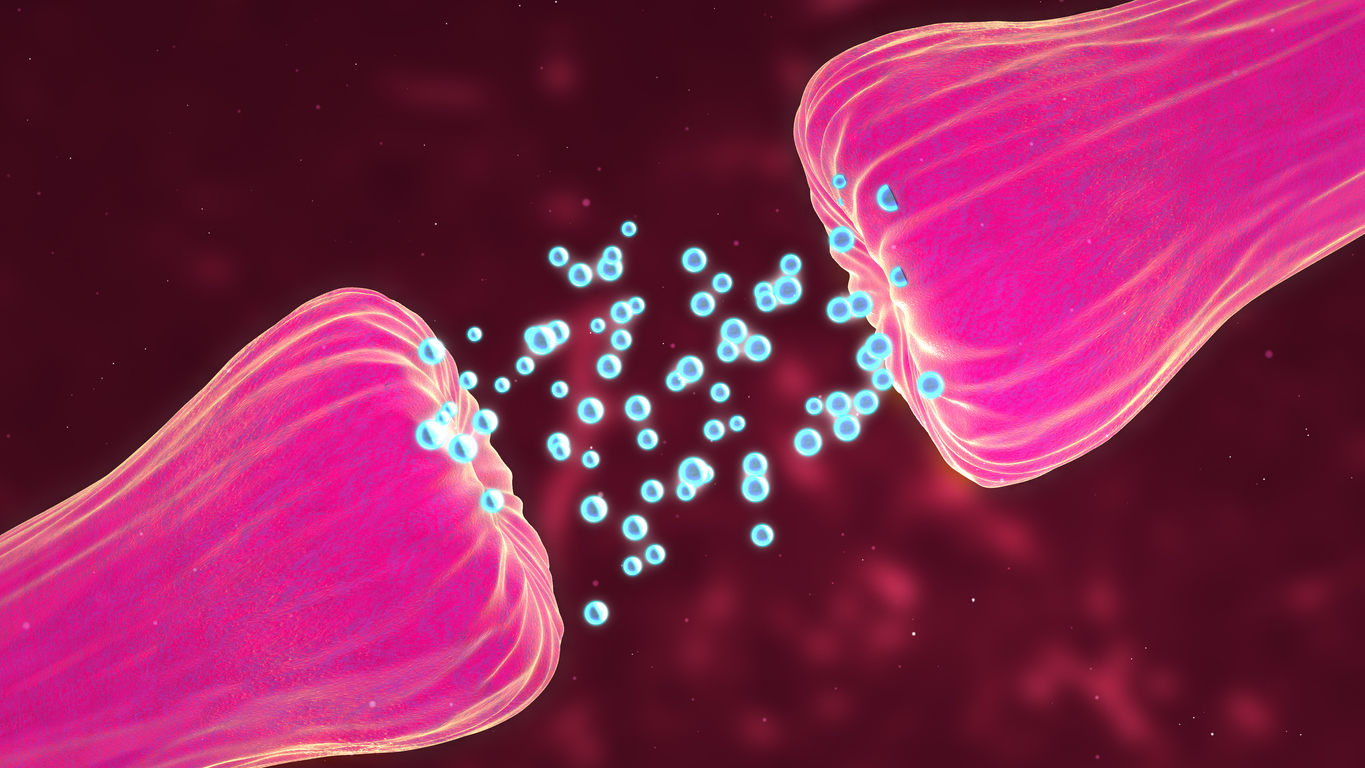

Electric current inputs are used to form a magnetic field in a typical loudspeaker, such as those used in headphones or an audio system, which moves a speaker membrane and the air above it, resulting in the sound that humans hear.

The new loudspeaker, on the other hand, uses a thin layer of structured piezoelectric material that moves when a voltage is put across it, displacing the air above it and producing sound.

The great majority of thin-film loudspeakers are freestanding because they must be able to flex freely in order to produce sound. You can’t make sound if you put loudspeakers on the surface. They wouldn’t be able to move freely and make noise.

To solve this problem, the MIT team devised a new thin-film loudspeaker design. The method uses microscopic domes attached to a thin layer of piezoelectric material that vibrate independently, rather than vibrating the entire piezoelectric material as is currently done. Despite the fact that each of these domes is only a few hairwidths in diameter, they are protected from contact with the mounting surface by spacer layers on both the top and bottom surfaces of the film, allowing them to vibrate freely. The same spacer layers protect the domes from wear and damage while the loudspeaker is being used. This increases the life of the speaker.

The loudspeaker was made by laser cutting microscopic holes in a thin sheet of PET – a lightweight plastic. The underside of the perforated PET layer was connected to the substrate with a thin PVDF film (a piezoelectric substance). When the adhesive sheets were done, they were put under a lot of pressure and a source of heat that was about 80 degrees Celsius.

The film bulged due to a pressure differential generated by the vacuum and heat source. Tiny domes protruded in regions where the PVDF is not halted by the PET layer as a result of the PVDF’s inability to penetrate the PET layer. This layer’s protrusions are self-aligned with the PET layer’s pores. The PVDF is then laminated with a PET layer on the reverse side, which acts as a spacer between the domes and the bonding surface.

This is a really simple and straightforward procedure, despite how complicated it sounds. If combined with roll-to-roll manufacturing technologies in the future, it will be possible to manufacture these loudspeakers at a high throughput rate. As a result, it could be mass-produced in large quantities, similar to wallpaper, which can be used for a variety of purposes such as wall coverings, car or plane interiors.

Superior quality with little energy consumption.

The domes are 15 microns tall and vibrate at a rate of half a micron per second, according to the researchers. They are about one-sixth the thickness of human hair. Because each dome makes its own sound, it takes a lot of tiny domes vibrating together to make a sound that can be heard.

It’s also worth noting that the team’s basic manufacturing method is highly adjustable, as the researchers can change the size of the PET holes to change the size of the domes they make. The resonance frequency of larger domes is lower than that of smaller domes, despite the fact that they displace more air and produce more sound. The resonance frequency of a device determines how well it works, and a lower resonance frequency results in audio distortion when the device is used.

Afterward, they tried a lot of different dome diameters and piezoelectric layer thicknesses to find the best combination of these two things.

They positioned their thin-film loudspeaker 30 centimetres away from a microphone and measured the sound pressure level in decibels to analyse it. The speaker produced high-quality sound at 66 decibels, which is considered conversational, when a steady current of 25 volts was sent through it at a frequency of 1 kilohertz (1,000 cycles per second). At a frequency of 10 kilohertz, the sound pressure level surged to 86 dB, which is nearly the same as city traffic.

According to the manufacturer, the device uses about 100 milliwatts of power per square metre of speaker space. For instance, depending on the type, a basic house speaker may require more than one watt of electricity to provide comparable sound pressure at a comparable distance.

Furthermore, because the tiny domes shake rather than the entire film, the loudspeaker has a high enough resonance frequency to be effective for ultrasound applications such as imaging. Ultrasound imaging uses sound waves with very high frequencies to make images, and higher frequencies make images more detailed than lower frequencies.

According to Bulovi (the senior author of the paper), the technology can also utilise ultrasound to determine a human’s location in a room, similar to how bats use echolocation, and then shape sound waves to follow the person as they move around. If the domes are covered with a reflective surface, thin-film vibrating domes with a reflecting surface can be used to generate light patterns for future display technologies. Vibrating membranes could provide a novel way of stirring molecules by vibrating when immersed in a liquid, enabling the creation of energy-efficient chemical processing techniques.

The research was originally published in IEEE Transactions on Industrial Electronics

Story Source: Original story written by Adam Zewe at the MIT News Office. Note: Content may be edited for style and length by Scible News.

Reference

J. Han, J. Lang and V. Bulovic, “An Ultra-Thin Flexible Loudspeaker Based on a Piezoelectric Micro-Dome Array,” in IEEE Transactions on Industrial Electronics, doi: 10.1109/TIE.2022.3150082.